Stringing equipment for pulling four conductors on 500KV overhead transmission line, 18 ton or 22 ton hydraulic puller, two of 2X40 KN or 4X50 KN hydraulic tensioner, SHWQN822 5 sheaves stringing blocks, 22mm or 24mm anti twisting braided steel wire rope.

- SA-YQ180G Hydraulic Puller

| Item No. |

07052 |

| Model |

SA-YQ180G |

| Stringing capacity |

1 pilot steel wire rope |

| Max. Pulling Force (KN) |

180 |

| Max. Continuous Pulling Force (KN) |

150 |

| Max. Pulling Speed (m/min) |

5km/h |

| Pulling force at max. speed: |

90 KN |

| Root Diameter of Bull wheel (mm) |

Φ760 |

| Number of grooves |

10 |

| Max. Steel rope Diameter (mm) |

Φ30 |

| Model of Diesel Engine |

Water cooled diesel engine |

| Power of Diesel Engine |

223.5 KW |

| Rotate Speed of Engine (rpm) |

2100 |

| Electrical System |

DC24V |

| Weight (kg) |

8000 |

| Dimension (m) |

5.78 x 2.35 x 2.82 |

Application: The hydraulic puller is used to pull pilot steel wire rope for conductors in overhead transmission line construction. It is fully hydraulic controlled, easily used and maintained.

Features:

- Closed hydraulic circuit,infinitely variable speed control in both rotating directions.

- The max pulling force for stringing operation can be preset, pulling force in the rope can be read on the line pull gauge.

- Automatic over pulling protection system

- Spring applied hydraulic released brake acts automatically in case of hydraulic failure to ensure safety.

- Hydraulic oil cooling system.

- Heat treated wear-proof bull wheels

- With rigid axle for towing at high speed, the machine looks beautiful.

- Hydraulic actuated pulling rope clamp for convenient reel change.

- Integral hydraulic self-loading reel winder with automatic level wind.

Main Components:

- Engine: Cummins water-cooled diesel engine. (China Joint Venture)

- Main variable displacement hydraulic pump and main motor: Rexroth (German)

- Reducer: R.R. (Italian)

- Reel winder motor: Danfoss (Danish)

- Main hydraulic valves: Rexroth

- Hydraulic instruments: WIKA (German)

- Radiator: AKG (German)

2A. Hydraulic Tensioner 18 Ton capacity SA-YZ4X50

2A. Hydraulic Tensioner 18 Ton capacity SA-YZ4X50

| Item No. |

07202 |

| Model |

SA-YZ4X50 |

| Max. Tension Force (KN) |

4X50 or 2 X 100 |

| Continuous Tension Force (KN) |

4X45 or 2X 90 |

| Max. Line Speed(km/h) |

5 |

| Max. Pulling back force (KN) |

4X45 or 2 X 90 |

| Max. Pulling back speed (km/h) |

4 x 1.2 |

| Diameter of Bullwheel (mm) |

Φ1600 |

| Number of grooves |

4 X 5 |

| Max. Conductor Diameter (mm) |

Φ42 |

| Model of Engine |

Water cooled Cummins |

| Power of Engine |

78 KW |

| Rotate Speed of Engine (rpm) |

2500 |

| Electrical system: |

DC24V |

| Weight (kg) |

12000 |

| Dimension (m) |

5.35 x 2.35 x 2.80 |

Application: The machine is used for stringing four or two bundled conductors or steel ropes.

Features:

- Closed hydraulic circuit, infinitely variable pull / tension force control in both directions.

- The max. tension / pull back force for conductor stringing operation can be preset, the tension /pull back force can be read from the tension gauge of machine.

- Spring applied hydraulic released brake acts automatically in case of hydraulic failure to ensure line safety

- Automatic overpull protection system.

- Hydraulic oil cooling system. Hydraulic front jack.

- Bull wheels lined with wear proof MC nylon lining segment.

- Optional 4 hydraulic power outlets to control 4 sets of hydraulic reel stands.

- Mounted on trailer with rigid axle for towing at max. speed of 15 km / h.

Main components:

- Engine: Cummins water cooled engine (USA)

- Main variable displacement pump and main motor: Rexroth (German)

- Reducer: R.R. (Italian)

- Main hydraulic valves: Rexroth (German)

- Hydraulic Instrument: WIKA (German)

- Radiator: AKG (German)

- Quick couplings: EMB (German)

2B. Hydraulic Tensioner SA-YZ2X40B for 2 bundled conductors

2B. Hydraulic Tensioner SA-YZ2X40B for 2 bundled conductors

| Item No. |

07192 |

| Model |

SA-YZ 2X40B |

| Max. Tension Force (KN) |

2X40 or 1X80 |

| Continuous Tension Force (KN) |

2X35 or 1X70 |

| Max. Stringing Speed(km/h) |

5 |

| Max. Pullback force (KN) |

2X40 or 1X80 |

| Max. Pullback speed (km/h) |

2 X 1.2 |

| Diameter of wheel (mm) |

Φ1500 |

| Number of grooves |

2X5 |

| Max. Conductor Diameter (mm) |

Φ40 |

| Model of Engine |

DEUTZ AIR COOLED |

| Power of Engine |

51 KW |

| Rotate Speed of Engine (rpm) |

2500 |

| Electrical system: |

DC24V |

| Weight (kg) |

4850 |

| Dimension (m) |

4.50 x 2.20 x 2.80 |

Application: It is suitable to string two bundled conductors or single conductor in overhead transmission line.

Features:

- Closed hydraulic circuit, infinitely variable tension force control in both directions.

- The max. tension/pull back force for conductor stringing operation can be presetted, the tension /pull back force can be read from the tension gauge of machine.

- Spring applied hydraulic released brake acts automatically in case of hydraulic failure to ensure line safety

- Hydraulic oil cooling system

- Bull wheels lined with wear proof MC nylon lining segments

- With 2 hydraulic power outlets to control 2 sets of hydraulic reel stands.

- Hydraulic front jack

- Mounted on trailer with rigid axle for towing at max. speed of 15 km/h

Main components:

- Engine: Deutz air-cooled diesel engine.

- Main variable displacement pump and main motor: Rexroth (German)

- Reducer: R.R. (Italian)

- Main hydraulic valves: Rexroth (German)

- Hydraulic Instrument: WIKA

- Quick couplings: EMB

- Radiator: AKG

- Optional Deutz air-cooled diesel engine (Made in German) SA-YZ2X40A 07191.

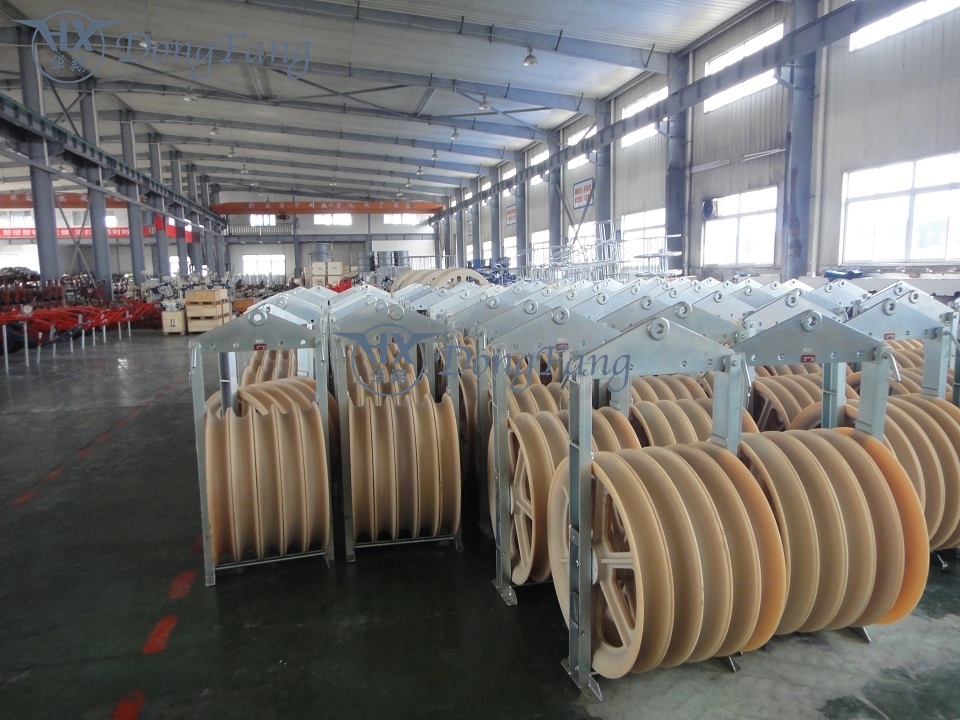

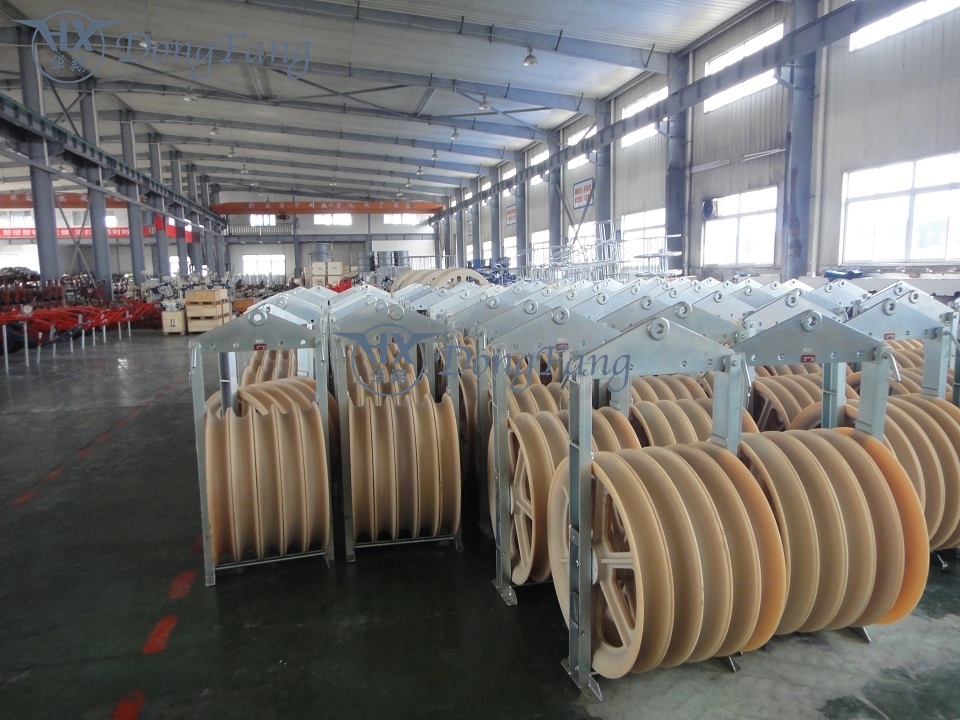

3. 5 Sheaves Stringing Blocks for four bundled conductors

3. 5 Sheaves Stringing Blocks for four bundled conductors

| Item No. |

Model |

Working Load (KN) |

Conductor Range (mm) |

Material of sheave |

Weight (kg) |

| 10143 |

SHWQN822 |

120 |

≤36 mm |

All Nylon |

170 |

Application: It is used for four bundled conductors stringing. Sheave size: Ø822 X Ø710 X 110

All the conductor sheaves are made of high strength nylon, the central sheave is specially designed with high strength, it is good for passing both of pilot steel wire rope and conductors.

All the sheaves are mounted on high strength heavy duty ball bearings.

The frame of stringing blocks is made of galvanized steel. Breaking Load: 3 Times of working load.

Option: The central sheave can be changed to steel sheave.

4. Anti twisting braided steel wire rope

4. Anti twisting braided steel wire rope

| Item No. |

Nominal diameter |

Min. Breaking Load (KN) |

Single strand diameter (mm) |

Normal T/S (N/mm²) |

Net Weight (kg/1000m) |

| 18214A |

24 |

360.00 |

Φ5.2 |

1960 |

1720 |

| 18212A |

22 |

320.00 |

Φ4.8 |

1960 |

1500 |

Anti twisting steel rope is specially braided from high strength, high flexible galvanized steel wire. The braided steel strand has high flexibility, complete stability to rotation under tension force. The wire rope is lubricated for long time usage.

It can homogeneously distribute the pressure between the elementary wires. The special rope can increase efficiency during the overhead transmission line stringing work. The rope is packed in steel drum which can be installed directly on the reel winder of puller.